WHAT IS DIGITAL TEXTILE PRINTING AND WHAT ARE ITS ADVANTAGES!

With the advent of technology, there has been a significant rise in the

way businesses operate today. One of the most promising developments in

technology is digital printing. Today digital printing technology

is adopted by many businesses that include the textile and diamond industry as

well. Gone are the days of conventional fabric printing; digital fabric printing has

taken a massive leap in the textile industry.

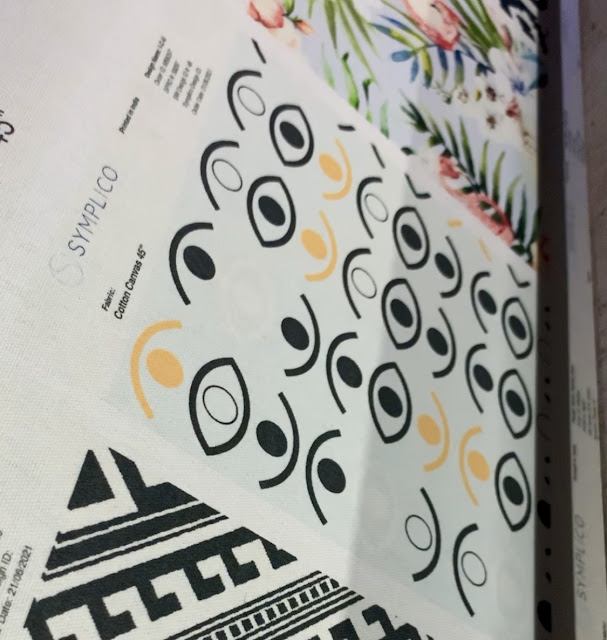

Digital

fabric printing has opened doors for boundless opportunities for creativity and

unparalleled prospects to enhance the quality and maintain the growing demand

of textile printing. With digital printing, anything can be printed

on any fabric easily and with the utmost perfection.

Digital Printing

In simple words, digital printing is the process of printing

digital-based images directly onto a variety of surfaces. Physical surfaces can

be in forms like paper, cloth, fabric, plastic, film, etc. In

digital printing, once the design is ready, you are set to go for the printing.

Unlike conventional printing, where multiple steps like preparing a screen,

spreading emulsion, etc., are required before finally printing any design on

the fabric.

Advantages of Digital Textile Printing (DTP)

Digital textile printing has many advantages over conventional printing.

The best aspect of printing is that there is no limitation in creativity and

usage of colors or repeat size. Unlike traditional fabric printing, where there

was a limitation to use multiple color shades on the fabric at a time,

with digital fabric printing, this is no

more a restriction. The digital textile

printing produces 16 million colors and shades. Therefore, the process is

time saving and sustainable.

Another great advantage of digital textile printing is that digital

printing is not limited to a maximum amount of rotary screens. Unlimited color

combinations can be applied, and hence, fine patterns with high resolution can

be experienced. As there is no need for color separation and screen engraving, it

helps in saving a lot of materials which in turn decrease the overall carbon

footprint.

Digital printing has proved to be a huge benefit for designers, textile

companies, and retailers. It saves them a lot of time and energy. It allows the

user to print quickly with a high accuracy level. In the case of traditional

printing, one must follow multiple steps and has to print quantity. Therefore

the process becomes too long.

Full customization is available with digital printing, without

compromising on precision and accuracy. The result will always be unparalleled.

Last but not the least, as pollution has become a serious problem on the

planet, considering textile as one of the biggest contributors, digital fabric

printing technology minimizes water and power consumptions as conventional

printing. It creates less pollution and does not release chemical waste like

other methods. The technology is environment

friendly.

Comments

Post a Comment